Full Electronic System Design

This is the most comprehensive of the electronic design services that our company offers. Includes everything, from the system’s architecture scheme to a working prototype.

It consists of the following steps:

System Architecture Design – Construction of a high-level diagram that provides the overview of the entire system. This diagram defines every system component as well as its connections to others.

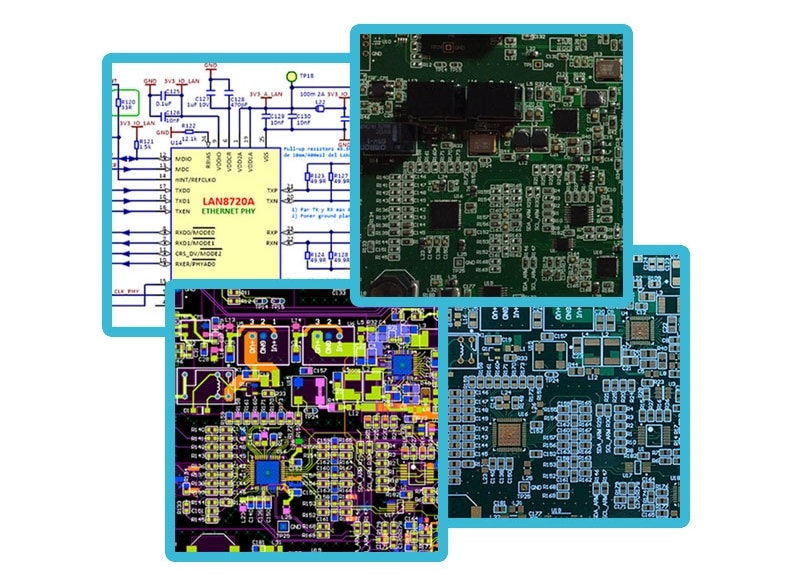

Schematic Design – Electrical circuit diagrams for every PCB board that will be part of the system.

PCB Design – CAD design of the system’s printed circuit boards. It may consist of one or more PCB boards, depending on the architecture and complexity of the system.

Prototype component sourcing – Purchase of electronic parts/components for the bare PCB boards prior to soldering.

PCB Assembly – Process of soldering the electronic parts on the PCB boards.

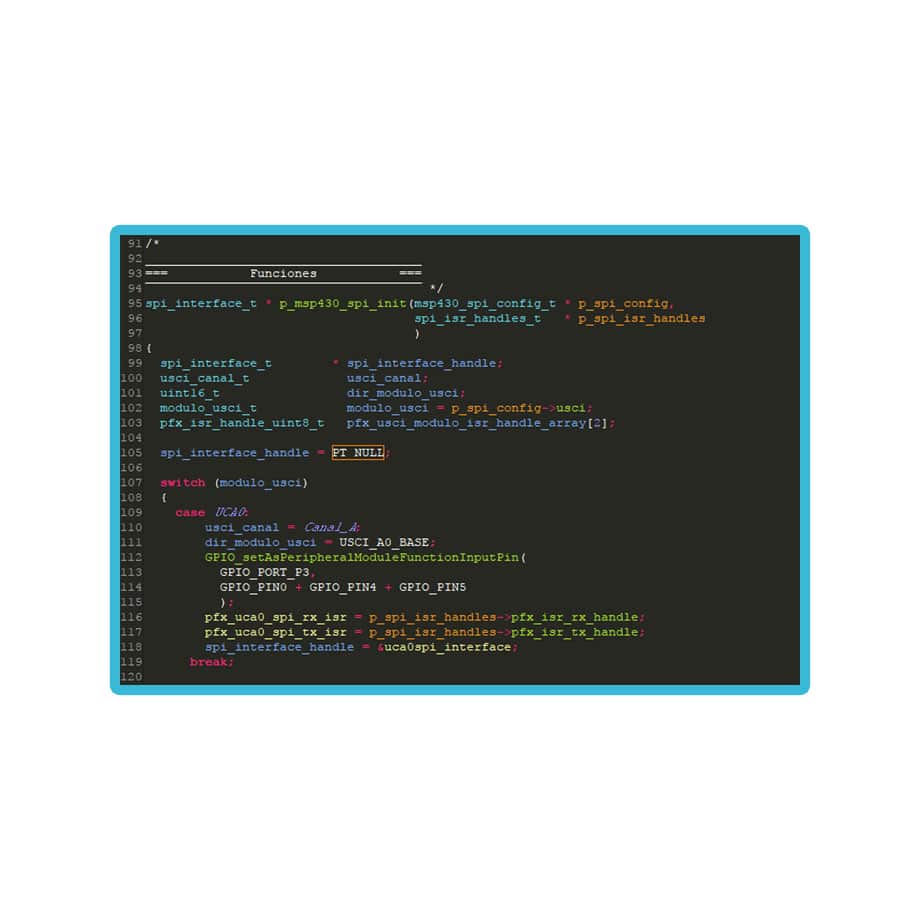

Firmware/Software Design – Code for every programmable device that is part of the system.

Testing – Hardware and Firmware/Software quality assurance.

To see some of our electronic designs, please visit our PCB Design Gallery.

The final product of the Full Electronic System Design service is a working prototype including its schematic and PCB design files, in addition to source code for every programmable device and an operating manual.

Electronic Hardware Design

You want to design the final firmware/software application but need someone else to carry out the electronic design of the hardware for you? No problem, we can design the hardware for your project and also provide you some code examples for testing the PCB board’s different features. This is the second most comprehensive of our electronic design services.

System Architecture Design – Construction of a high level diagram that provides the overview of the entire system. This diagram defines every system’s component as well as its connections to others.

Schematic Design – Electrical circuit diagrams for every board that will be part of the system.

PCB Design – CAD design of the system’s printed circuit boards. It may consist of one or more PCB boards, depending on the architecture and complexity of the system.

Prototype component sourcing – Purchase of electronic parts/components to be installed on the PCB boards.

PCB Assembly – Purchase of electronic parts/components for the bare PCB boards prior to soldering.

Firmware Test Block Design – Development of minimal code examples that will guide the customer on how to use every hardware resource.

The final product of the Electronic Hardware Design service are the fully assembled PCB boards including their schematic, PCB design files, BOM and source code examples.

Firmware Design

This service is available to our customers that have already designed their printed circuit boards through the Full Electronic System Design or Electronic Hardware Design services. It consists in designing new firmware or firmware updates for programmable devices that are installed on the PCB boards. It consists of the following tasks:

Firmware design – Design process for deploying firmware/software for the first time or for updates to current versions.

Testing – Firmware quality assurance.

The final product of the Firmware Design service consists of the complete source code files as well as the operating manual.

Note: This service is available for our PCB designs only.

PCB Manufacturing

This service is available to our customers that have already designed their printed circuit boards through the Full Electronic System Design or Electronic Hardware Design services and want to manufacture them. This is service is not available for third party hardware designs.

It consists of the following tasks:

Component sourcing – Purchase of electronic parts/components for the bare PCB boards prior to soldering.

PCB Manufacture – Process for producing bare PCB boards.

PCB Assembly – Process of soldering the electronic parts on the bare PCB boards.

Programming – Process of loading firmware/software binaries into the PCB board’s programmable devices.

Testing – Quality checking for the assembled boards.

The final product of the PCB Manufacturing service are the fully assembled and tested PCBs.